Harness Inspection Form

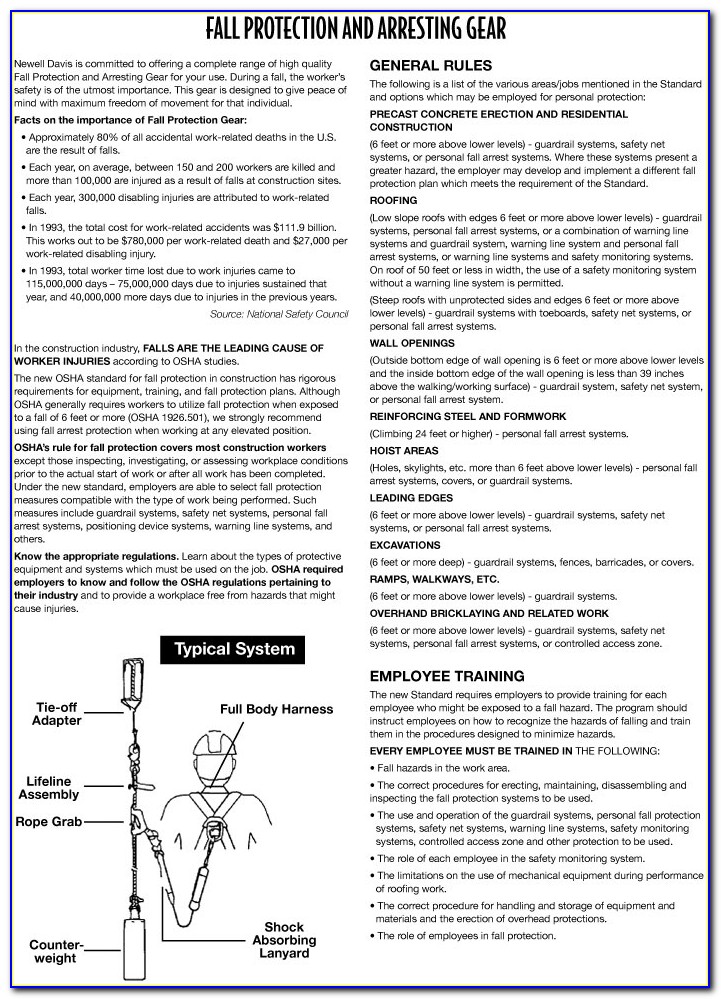

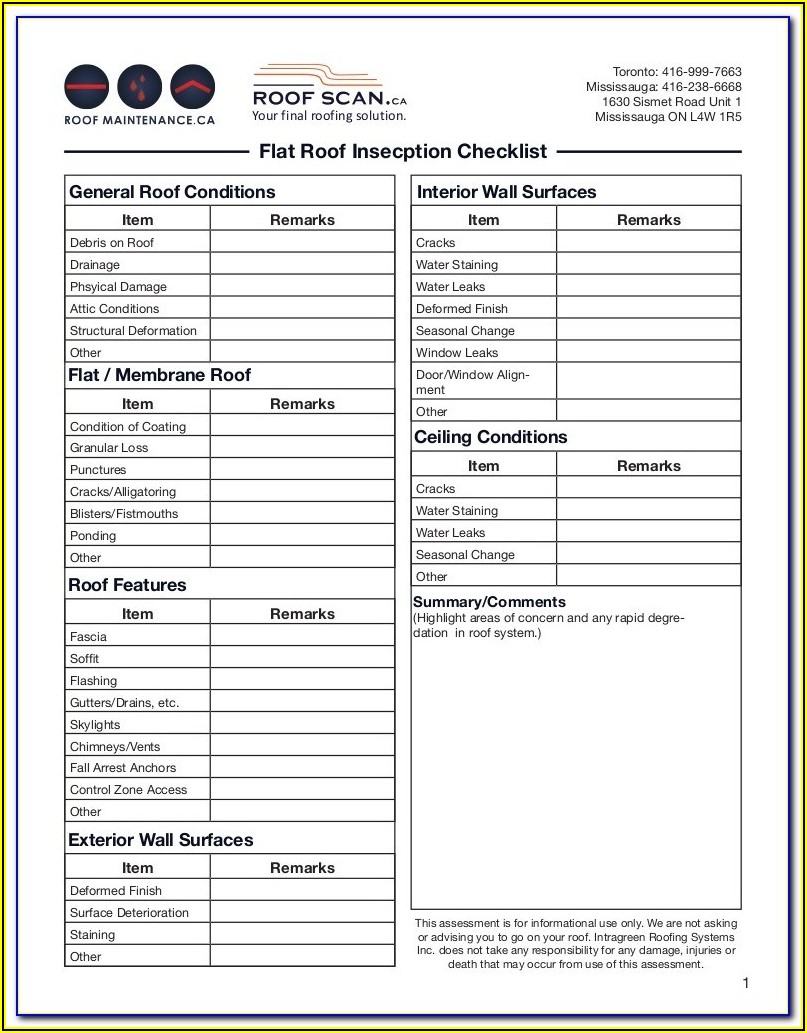

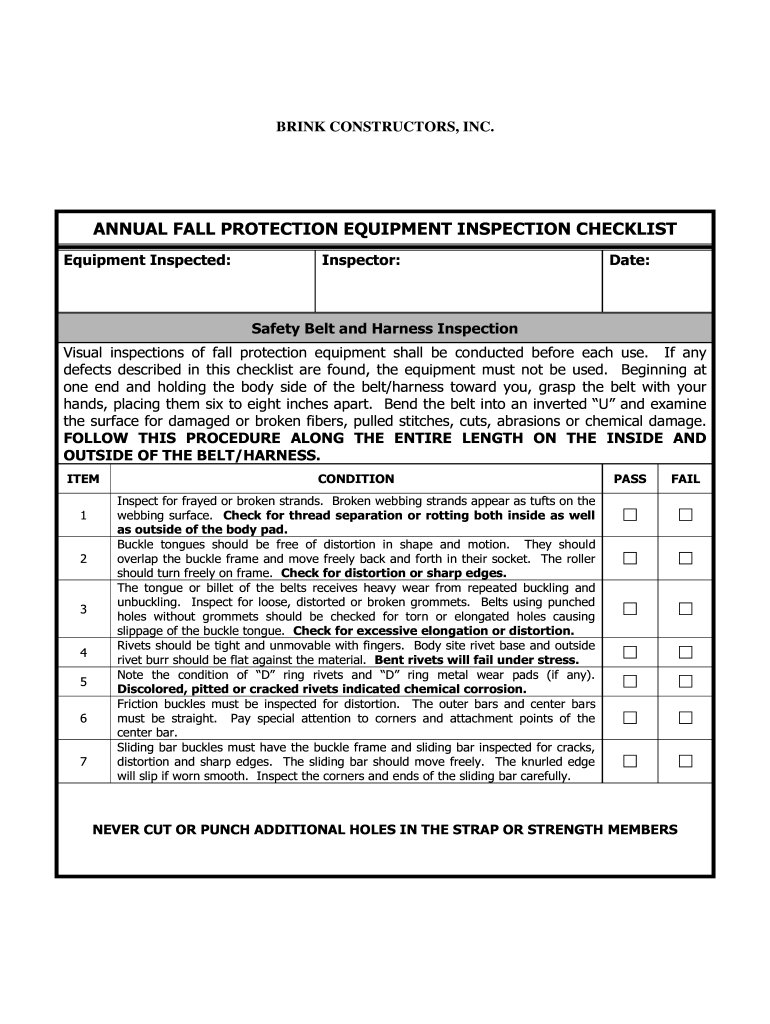

Harness Inspection Form - Destroy immediately serial # date of mfg. Web a safety harness equipment inspection checklist is used by workers at heights to ensure that a safety harness is in good condition before use and reduce the risk of falling. Web full body harness inspection sheet. Pass, safe for use red: Web 1.1 safety belt 1.2 full body harness 1.3 shock absorver 1.4 lanyard components 1.5 anchor or anchor point 1.6 rope grab or fall arrestor 1.7 lifeline components a safety harness is a device that is shaped like a series of ropes with certain patterns. Model # description inspection date pass fail inspected by inspection date pass fail inspected by inspection date. Frequency of inspection in the following categories: Every harness must have a legible tag identifying the harness, model, date of manufacture, name of manufacturer, limitations and warnings. Display your checklist results in a timeline or register view format with a single click. Full body harness ohsa 1926.502(d)(21) personal fall arrest systems shall be inspected prior to each use for wear, damage, and other deterioration, and defective components shall be removed from service.

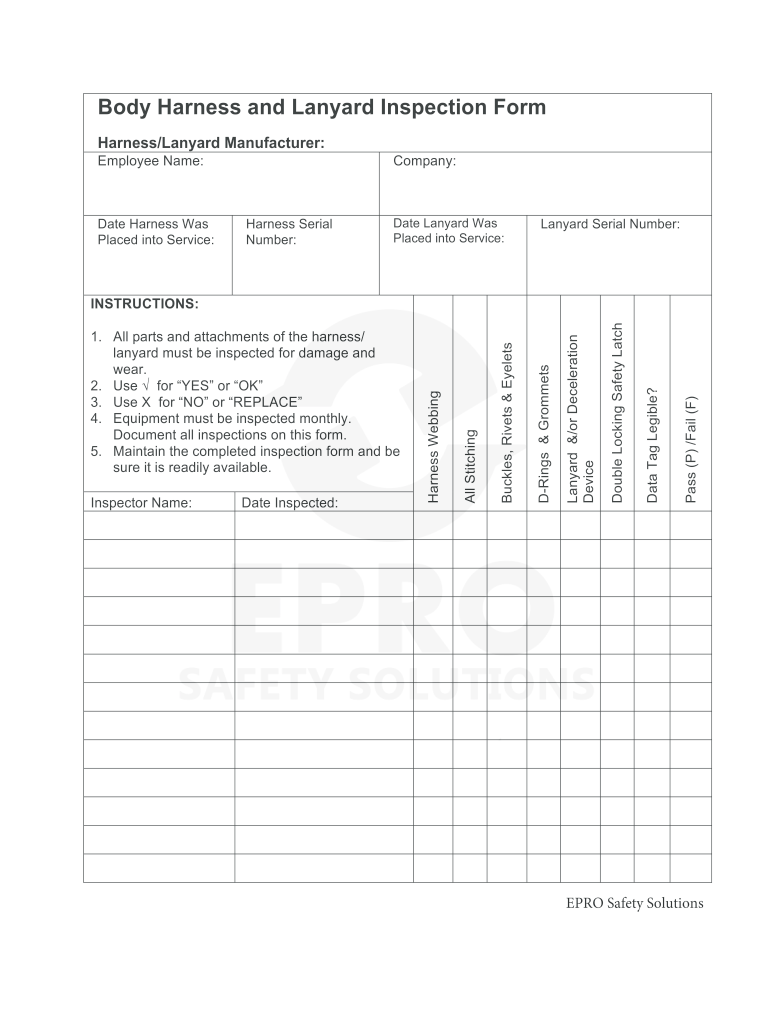

Web a safety harness equipment inspection checklist is used by workers at heights to ensure that a safety harness is in good condition before use and reduce the risk of falling. Web 1.1 safety belt 1.2 full body harness 1.3 shock absorver 1.4 lanyard components 1.5 anchor or anchor point 1.6 rope grab or fall arrestor 1.7 lifeline components a safety harness is a device that is shaped like a series of ropes with certain patterns. Web full body harness inspection sheet. Begin by capturing the identification and intended usage of the harness or lanyard you are inspecting. Display your checklist results in a timeline or register view format with a single click. Model # description inspection date pass fail inspected by inspection date pass fail inspected by inspection date. When inspecting your harness look for stitching that may be broken, burned or pulled and stitching or rivets at hardware attachment points. Pass, safe for use red: Safety harnesses also have different types of components that have different. Web access and complete your harness inspection checklist directly on site using a mobile or tablet or using a computer as well.

Web a safety harness equipment inspection checklist is used by workers at heights to ensure that a safety harness is in good condition before use and reduce the risk of falling. Safety harnesses also have different types of components that have different. A safety harness inspection should be personally conducted before each use. Frequency of inspection in the following categories: Model # description inspection date pass fail inspected by inspection date pass fail inspected by inspection date. Psg safety harness inspection form Web fall protection harness inspection. Web 6.1 inspection 6.1.1 equipment shall be inspected by the user before each use and, additionally, by a competent person other than the user at intervals of no more than one year. Web 1.1 safety belt 1.2 full body harness 1.3 shock absorver 1.4 lanyard components 1.5 anchor or anchor point 1.6 rope grab or fall arrestor 1.7 lifeline components a safety harness is a device that is shaped like a series of ropes with certain patterns. Full body harness ohsa 1926.502(d)(21) personal fall arrest systems shall be inspected prior to each use for wear, damage, and other deterioration, and defective components shall be removed from service.

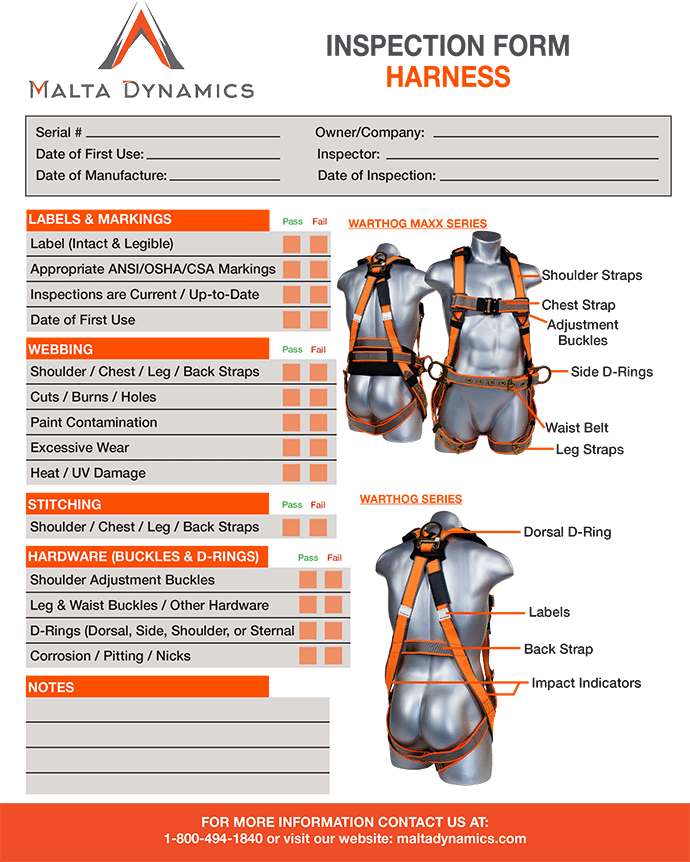

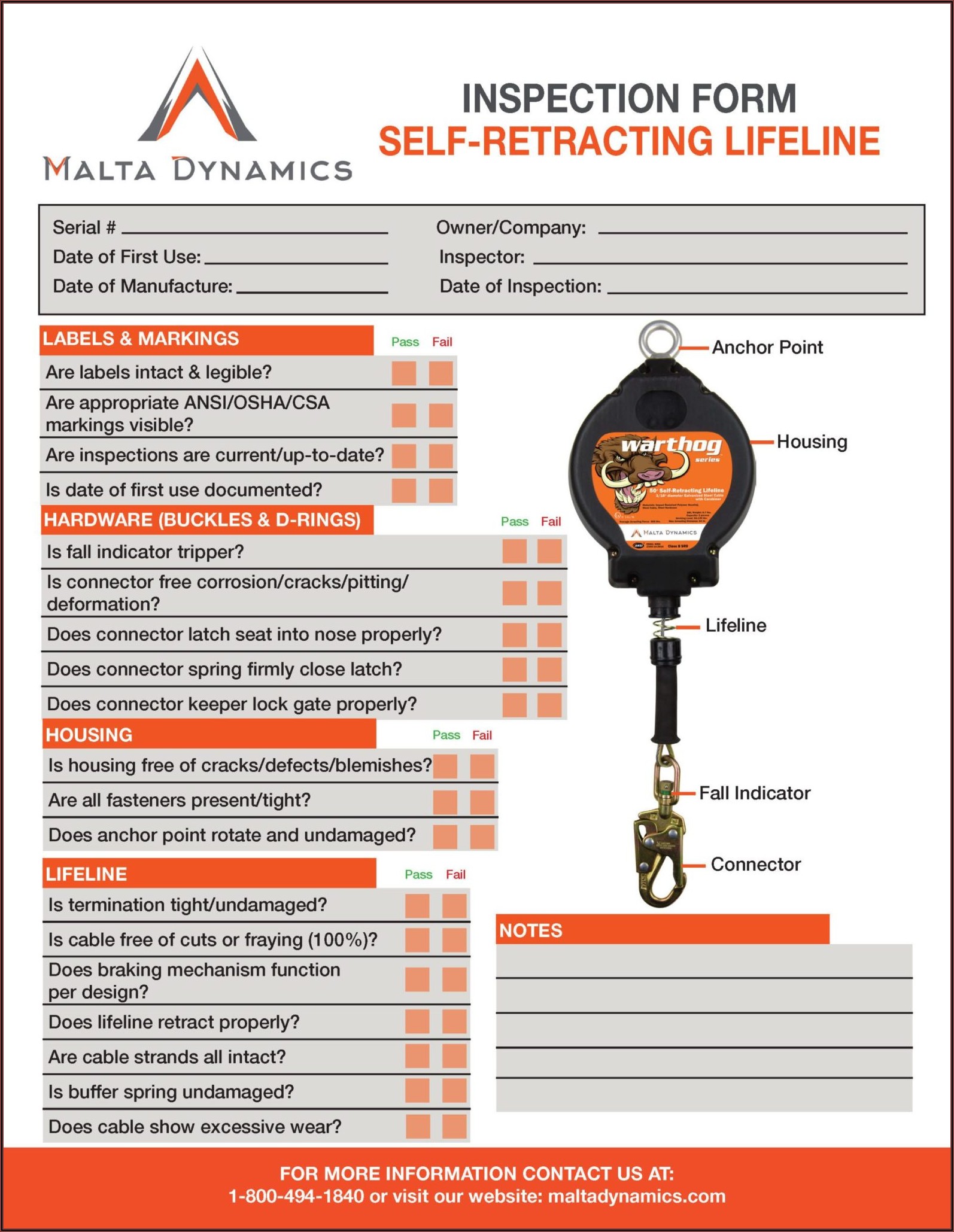

Inspection Forms Malta Dynamics

Web fall protection equipment inspection log green: Full body harness ohsa 1926.502(d)(21) personal fall arrest systems shall be inspected prior to each use for wear, damage, and other deterioration, and defective components shall be removed from service. Web 6.1 inspection 6.1.1 equipment shall be inspected by the user before each use and, additionally, by a competent person other than the.

Harness And Lanyard Inspection Template Form Resume Examples

Begin by capturing the identification and intended usage of the harness or lanyard you are inspecting. Model # description inspection date pass fail inspected by inspection date pass fail inspected by inspection date. Web fall protection equipment inspection log green: Web full body harness inspection sheet. Safety harnesses also have different types of components that have different.

Full Body Harness Inspection Form National Safety 6910 S. 196th st

Web 1.1 safety belt 1.2 full body harness 1.3 shock absorver 1.4 lanyard components 1.5 anchor or anchor point 1.6 rope grab or fall arrestor 1.7 lifeline components a safety harness is a device that is shaped like a series of ropes with certain patterns. Pass, safe for use red: Full body harness ohsa 1926.502(d)(21) personal fall arrest systems shall.

Harness And Lanyard Inspection Form Fill and Sign Printable Template

Full body harness ohsa 1926.502(d)(21) personal fall arrest systems shall be inspected prior to each use for wear, damage, and other deterioration, and defective components shall be removed from service. Model # description inspection date pass fail inspected by inspection date pass fail inspected by inspection date. Web full body harness inspection sheet. Frequency of inspection in the following categories:.

Harness Inspection Template Harness Safety Inspection Check Book

Model # description inspection date pass fail inspected by inspection date pass fail inspected by inspection date. Web 6.1 inspection 6.1.1 equipment shall be inspected by the user before each use and, additionally, by a competent person other than the user at intervals of no more than one year. Frequency of inspection in the following categories: Destroy immediately serial #.

Safety Harness Inspection Checklist Template Uk Form Fill Out and

Frequency of inspection in the following categories: Begin by capturing the identification and intended usage of the harness or lanyard you are inspecting. •check tag for date of manufacture and remove from service if past adopted service life policy Web full body harness inspection sheet. Every harness must have a legible tag identifying the harness, model, date of manufacture, name.

Full body Harness Inspection Form format Samples Word Document Download

Frequency of inspection in the following categories: Destroy immediately serial # date of mfg. Web full body harness inspection sheet. Safety harnesses also have different types of components that have different. Pass, safe for use red:

Harness Inspection Template Body Harness And Lanyard Inspection Form

Pass, safe for use red: Frequency of inspection in the following categories: Web 6.1 inspection 6.1.1 equipment shall be inspected by the user before each use and, additionally, by a competent person other than the user at intervals of no more than one year. Begin by capturing the identification and intended usage of the harness or lanyard you are inspecting..

Safety Harness And Lanyard Inspection Checklist Form Resume

Web full body harness inspection sheet. Web a safety harness equipment inspection checklist is used by workers at heights to ensure that a safety harness is in good condition before use and reduce the risk of falling. Download, print or send your completed full body harness inspection docs as formatted pdfs with your company logo. Psg safety harness inspection form.

Osha Safety Harness Inspection Form

Frequency of inspection in the following categories: Download, print or send your completed full body harness inspection docs as formatted pdfs with your company logo. Display your checklist results in a timeline or register view format with a single click. Web access and complete your harness inspection checklist directly on site using a mobile or tablet or using a computer.

Frequency Of Inspection In The Following Categories:

Every harness must have a legible tag identifying the harness, model, date of manufacture, name of manufacturer, limitations and warnings. Pass, safe for use red: Web 1.1 safety belt 1.2 full body harness 1.3 shock absorver 1.4 lanyard components 1.5 anchor or anchor point 1.6 rope grab or fall arrestor 1.7 lifeline components a safety harness is a device that is shaped like a series of ropes with certain patterns. Web fall protection equipment inspection log green:

Safety Harnesses Also Have Different Types Of Components That Have Different.

Web full body harness inspection sheet. A safety harness inspection should be personally conducted before each use. Display your checklist results in a timeline or register view format with a single click. Full body harness ohsa 1926.502(d)(21) personal fall arrest systems shall be inspected prior to each use for wear, damage, and other deterioration, and defective components shall be removed from service.

Web A Safety Harness Equipment Inspection Checklist Is Used By Workers At Heights To Ensure That A Safety Harness Is In Good Condition Before Use And Reduce The Risk Of Falling.

Begin by capturing the identification and intended usage of the harness or lanyard you are inspecting. Web fall protection harness inspection. Psg safety harness inspection form Web access and complete your harness inspection checklist directly on site using a mobile or tablet or using a computer as well.

Web 6.1 Inspection 6.1.1 Equipment Shall Be Inspected By The User Before Each Use And, Additionally, By A Competent Person Other Than The User At Intervals Of No More Than One Year.

•check tag for date of manufacture and remove from service if past adopted service life policy Destroy immediately serial # date of mfg. Model # description inspection date pass fail inspected by inspection date pass fail inspected by inspection date. When inspecting your harness look for stitching that may be broken, burned or pulled and stitching or rivets at hardware attachment points.